Root CNC (DIY CNC)

For some weird reason my desire to build a CNC router dates my highschool times, when I learned at school to drive stepper motors.

Long time after with some friends we decided to build a CNC router from scratch, using an existing open source design with some personal flavors such as a custom Z-axis designed by me.

The base project was a RootCNC v3, a relatively simple and inexpensive design.

It was a beautiful project that involved many hours of 3d printing parts and a couple weekends assembling the machine and tweaking it.

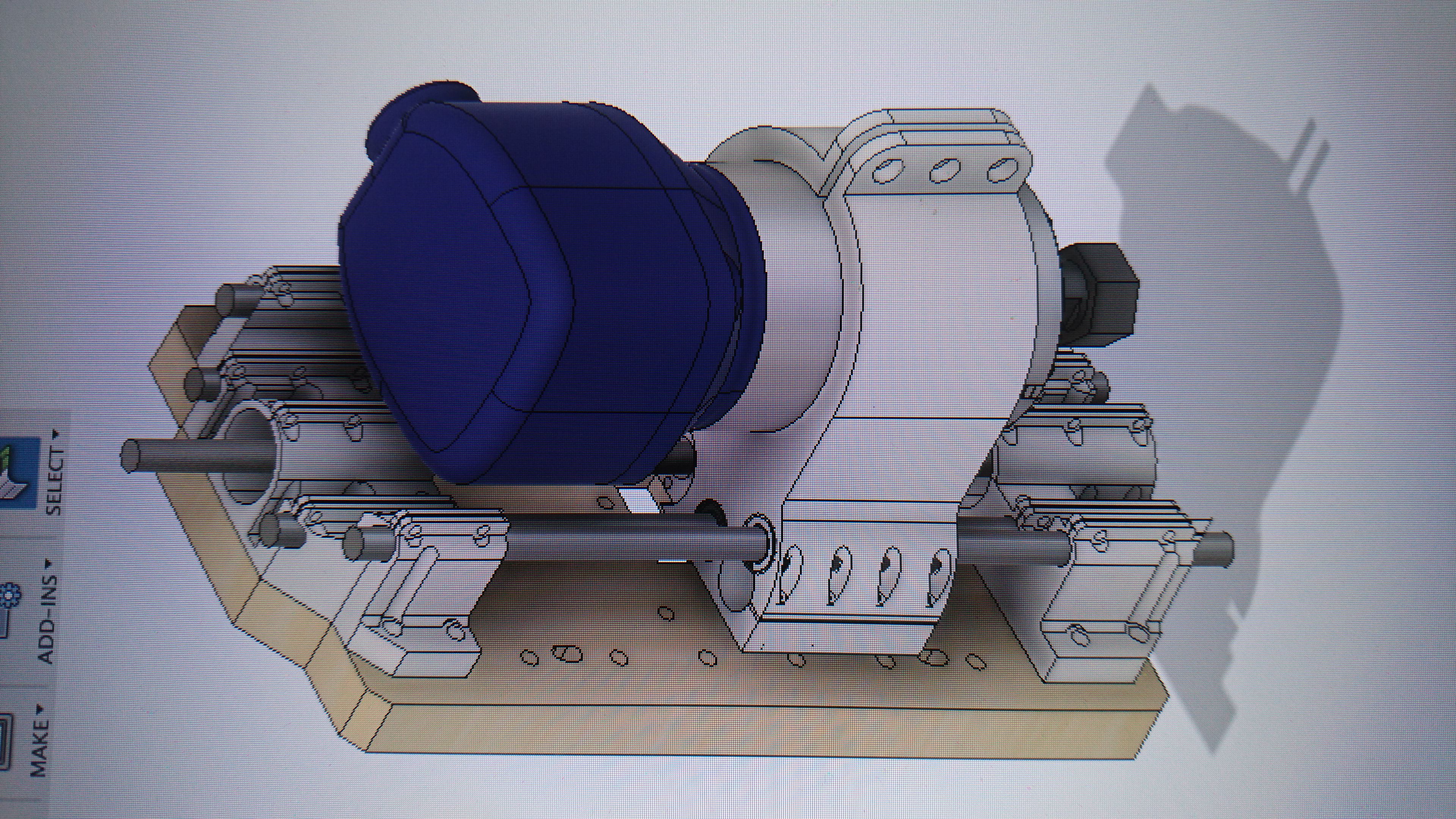

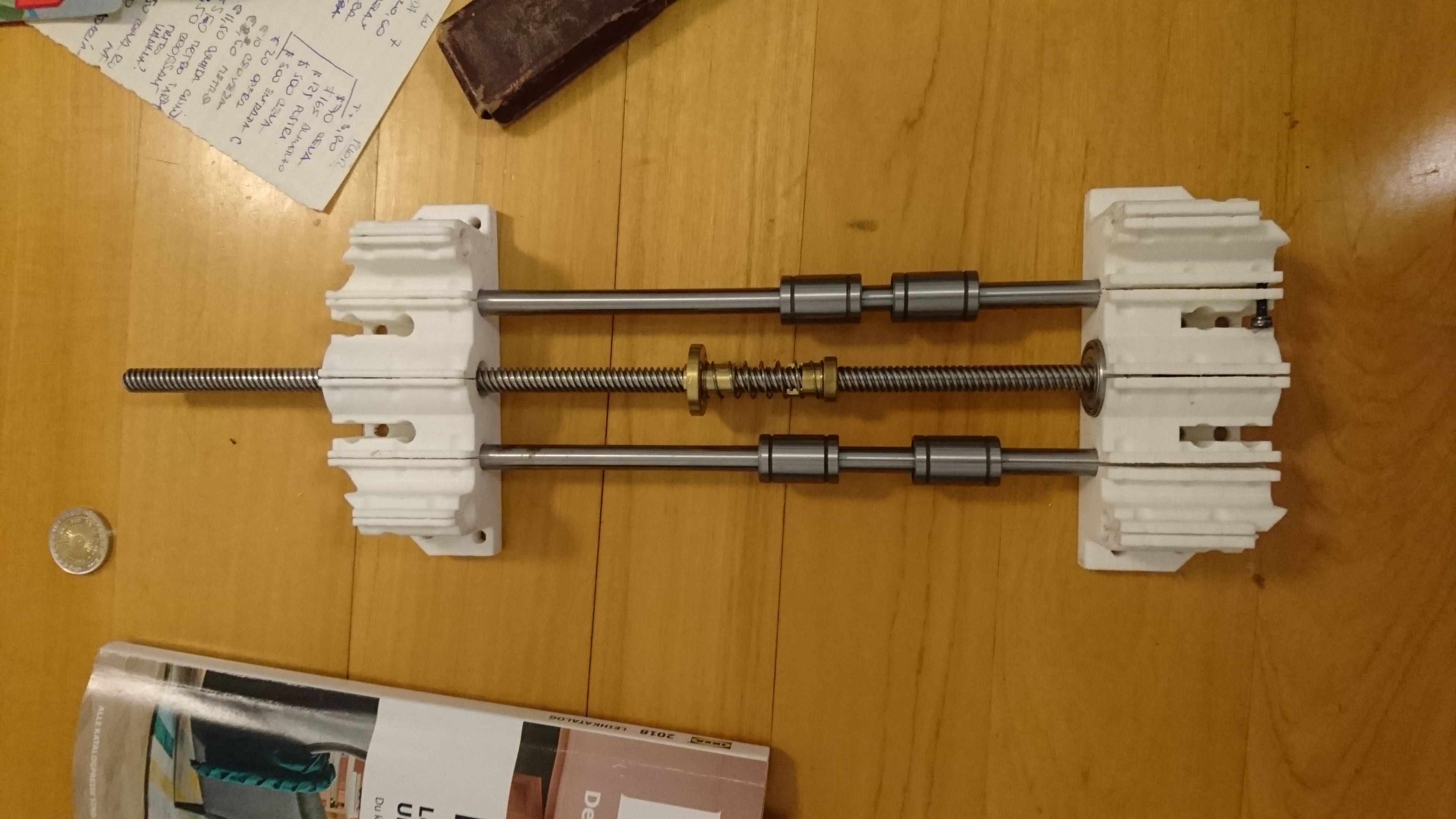

The original Z-axis used linear rails which were quite expensive/difficult to get in Argentina, so I decided to design a brand new mechanism from scratch, surprisingly it worked quite well. I used Autodesk Fusion 360 for the design.

Also, instead of using aluminium square pipes we used rectified steel ones, another huge cost saving.

Some photos of the making of:

- Custom Z-axis:

|

|

- Things tend to get messy in my apartment… my neighbors, delighted.

- First movements…

- It’s alive!

- Maker pride