SmartrapCore (DIY 3DP)

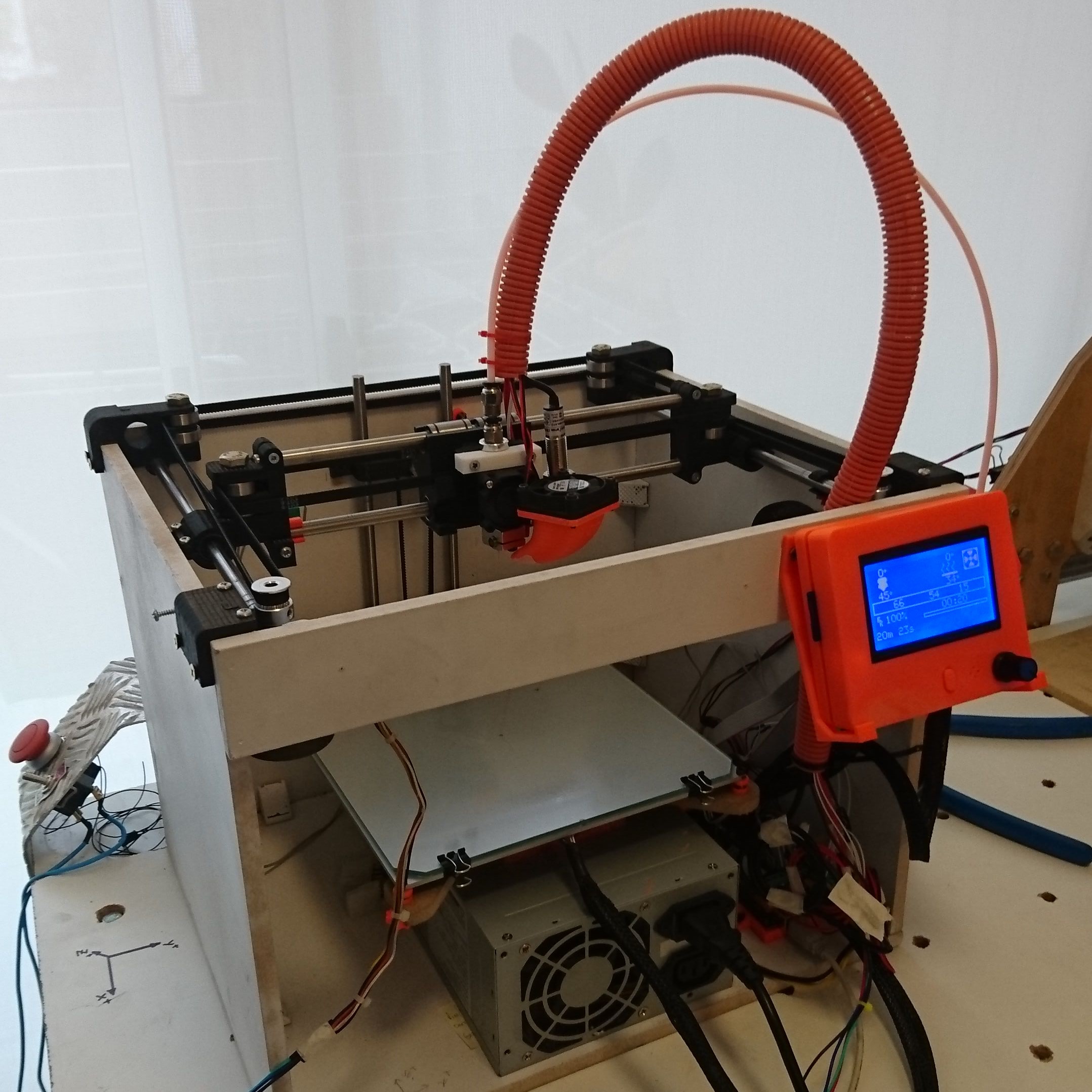

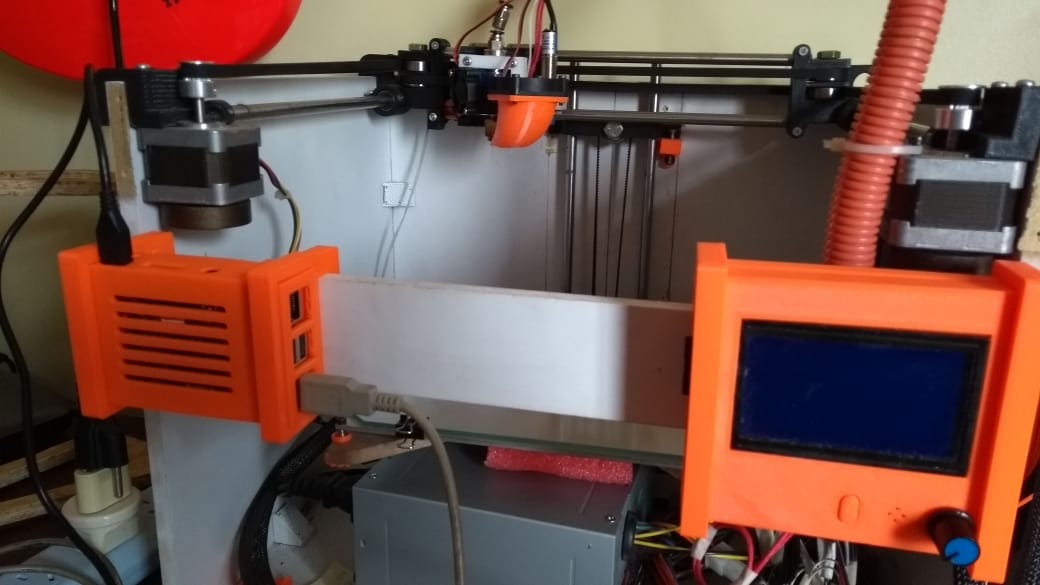

I decided to build a coreXY 3D printer based on a open source design called SmartrapCore, using some sacavanged materials such as Epson printers stepper motors and piece of MDF that I found on the street and a ~30 bucks Ramps 1.6 Kit from Aliexpress that a friend bought. All the pieces are designed in a parameterized OpenSCAD project which makes very easy to adapt the dimensions to your needs and materials.

To be honest, I was surprised by the results, didn’t expected much because used smaller motors than the usual.

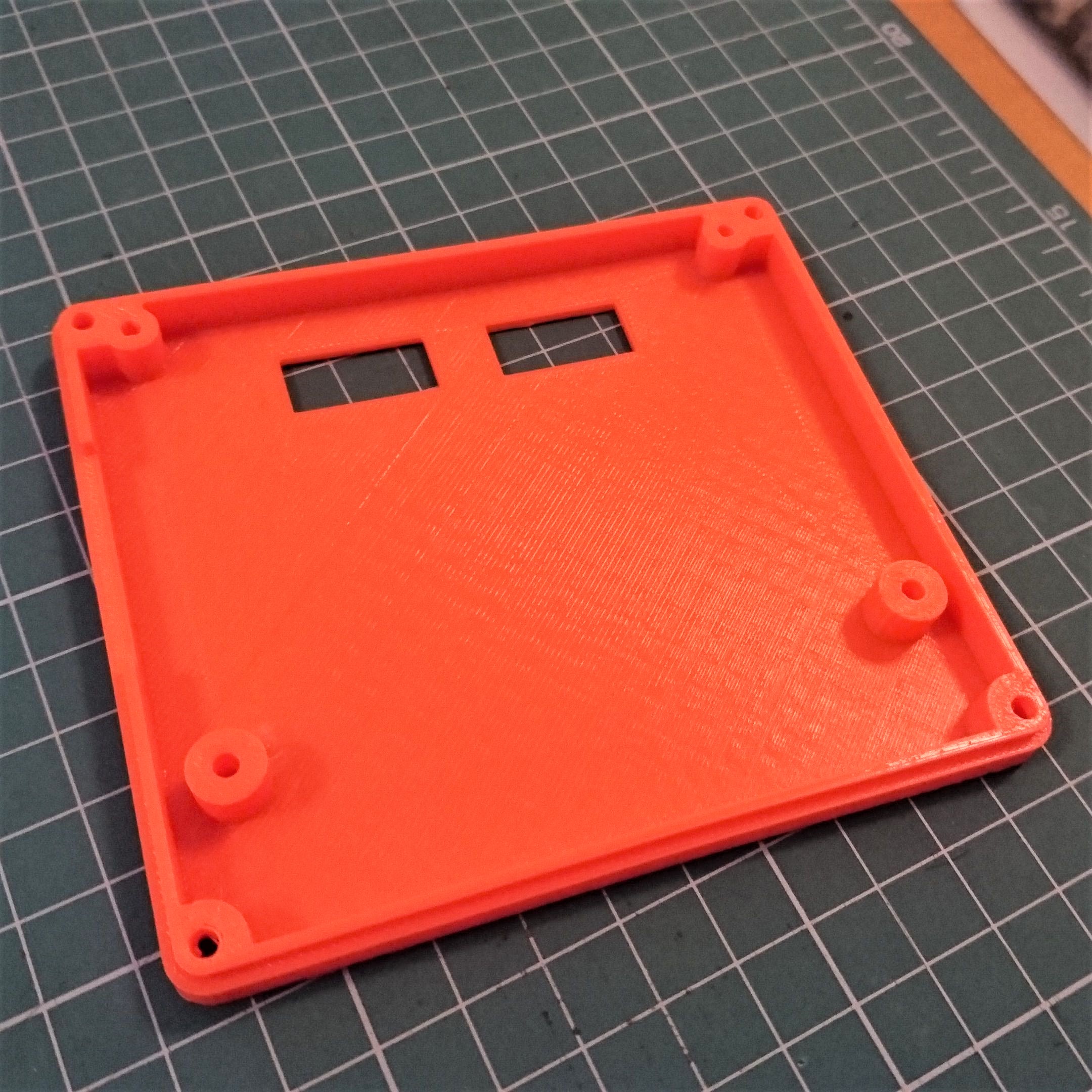

It was quite easy to assemble and paying it’s respects to the RepRap philosophy the machine was quickly printing it’s own upgrades.

Yes, it looks like a 3D printer that came out of a Mad Max movie, I didn’t have the time yet to beautify it. But it works, that’s what matters.

Some photos and videos of the making of:

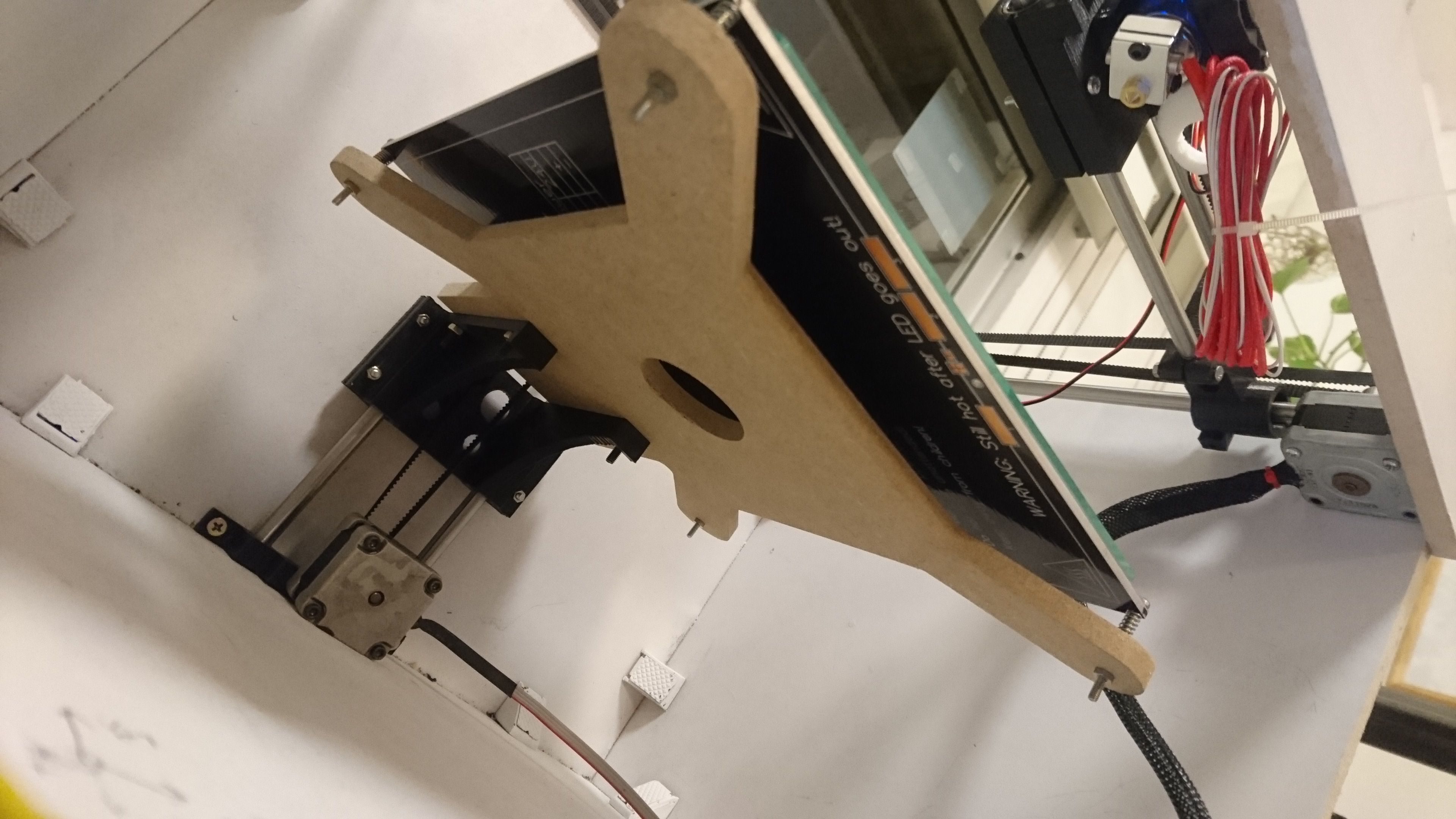

- Used reclaimed MDF panels found of the street to build the frame.

- First mechanical assembly.

- First homing.

- It’s alive!

Some minor upgrades:

- Made a better bed frame with the help of the CNC.

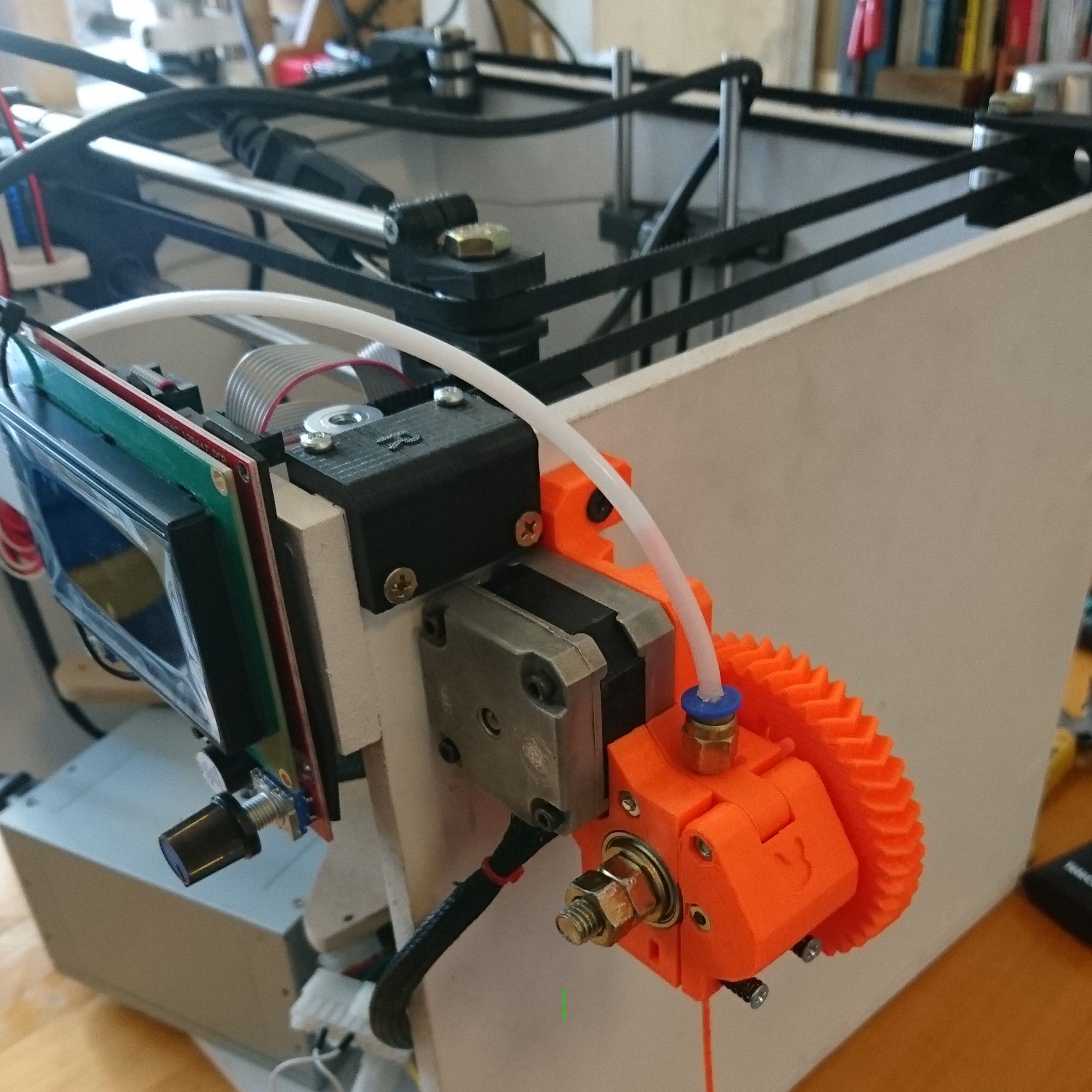

- Printed it’s own new geared extruder due to the size (small) motor I was using, because it was loosing steps at “high” printing speeds.

- After this point I handed over the printer to my friend Dario and he carried on some aesthetics upgrades.

Some prints made with this machine: